Attributes of UHMWPE Pipe

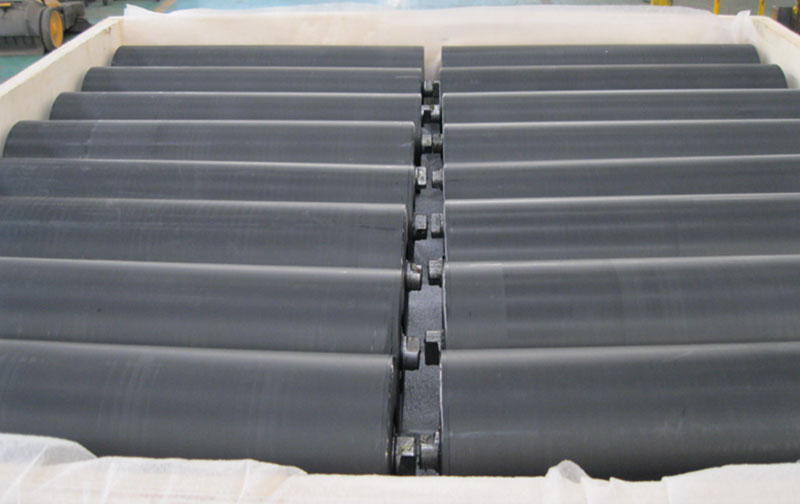

UHMWPE Roller Benefits:

1. Abrasion resistance and long life

The shell is made from UHMWPE which has abrasion resistance 10 times that of HDPE and 7 times that of steel. UHMWPE rollers have been subjected to continuous abrasion in very extreme quarrying, coastal and industrial applications.

2. Impact resistance and Impact energy absorbing

UHMWPE has the highest impact strength of any engineering plastics, about three times which of nylon, five times that of ABS, withstands repeated impaction, even at -196 it is tough, together with its superior abrasion and corrosion resistance. UHMW-PE has made itself ideally suited for industrial applications in complicate and rough environments.

3. Effective sealing system

The labyrinth seal prevents most of the dust from getting into the bearing house, and no water could leak in.

The narrow clearance between bearing shell and shaft forms the second sealing, the bearing shell are made of UHMWPE which has a very low surface energy and are anti-adhesion, so it is repulsive to dust and water. It is quite difficult for dust to get through the narrow channel.

4. Light weight and energy saving

UHMWPE rollers are only one third less in weight than steel roller, they are even lighter than HDPE roller, since they have superior strength. Light weight and low friction result in considerable energy saving.

5. Reduced belt damage

UHMWPE pipe is self-lubricant, and prevent the adhesion of any transfer material, so no damage was caused to conveyor belt, even in case of roller be stopped.

6. Noise reduction

UHMWPE is a much better noise debase material than HDPE, UHMWPE rollers generate much less noise than conventional steel roller, they are environmentally friendly.

7. Corrosion resistance

UHMWPE roller can withstand humidity, corrosive chemicals, acids, salt and alkali.

8. No sticking

UHMWPE could stick any material, so no conveyor material will be stacked to roller surface.

Comparison Between UHMWPE and Steel Rollers

| Properties | UHMWPE Roller | Steel Roller |

| Chemical resistance(strong acid/alkali) | Good | Bad |

| Toughness | No Breakage | No Breakage |

| Sticking&Caking | No Sticking | Sticking |

| Friction Coefficient | Low(0.1-0.12) | High(0.68-0.80) |

| Anti-magnetic | Good | Bad |

| Belt damage | No belt damage | Belt easy to be damaged |

| Power consumption | 0.85-0.9 | 1 |

| Noise&Vibration | Low | High |

| Weight | 3 | 10 |

| Installation&Maintenance | Easy | Difficult |

| Water Absorption | Low | Low |

| Impact resistance | Good | Good |

| Service life | 3-5 years | 1-2 years |

Key Application of UHMWPE Pipe